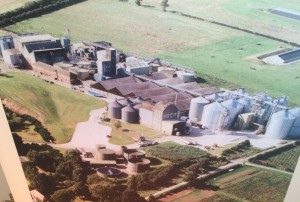

We drove to Muntons Malting and had a first class tour with our group.

We started off with a presentation and coffee and a good chat about the company.

Here a few trucks are dropping off.

Raw barley is dropped off after its’ contents are evaluated for various conditions to allow acceptance

Next the barley is cleaned and processed into the system. Equipment separates the smaller kernels from the larger ones. The smaller ones are sold to farmers for feed. The barley is cleaned and moisture content is then stabilized and the kernels are off to storage for some months until they are ready to be germinated.

After the storage,the steeping starts they raise the moisture in the kernel. In the video below, the kernels are doing just that.

There were a number of these big conical tanks in this part of the plant

Here is a video of another part of the same process as the grains are being drained from the vat.

Then on to the germination area.

Here is a kernel from the above.

Then it’s off to the dryers when the germination gets to the point the guys at the helm decide. I have no photos of the dryers because it was VERY hot and humid inside them and none of my photos came out.

Here is some of the smaller amounts going out for delivery.

You must be logged in to post a comment.