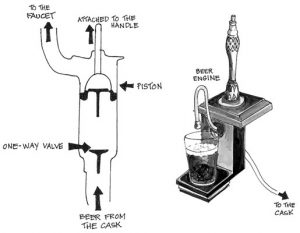

The beer engine is also know as a Hand Pull.

From http://www.dummies.com/how-to/content/dispensing-real-ale.html

“A beer engine is a manual device used to siphon beer from a cask. Because it requires a bartender to literally pull the beer through the beer line, beer engines are also referred to as handpulls.”

Good information above from the linked website. The handpull has a cylinder and a piston mechanism that pulls and pushes the beer to the gooseneck. On some handpulls, this cylinder is not cooled. This causes the beer in the cylinder to warm up. The server needs to be aware of this. Real Ale is served warmer than CO2 pushed beer, but it is not warm! If the beer sits and warms up, the servers’ responsibility is to NOT serve this until the warm beer is pulled off and the correct temperature (50f-55f) beer enters the glass. Also don’t use a glass that has just come out of the dishwasher.

Also, it can be gravity fed from the cask:

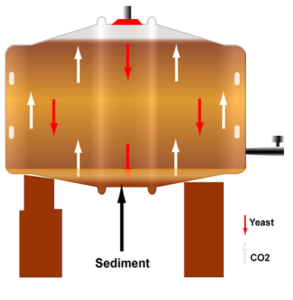

Internal conditions of a cask

Since cask beer has to be served from the container that the second fermentation was accomplished in (creating the carbonation), awareness of what is going on inside the cask is necessary.

Anytime you carbonate naturally, you have sediment that precipitates from this secondary fermentation. This is true if it is a bottle, cask or keg. If you buy a bottle of beer that says it is bottle conditioned you will find a layer of sediment on the bottom (a correct pour of a bottle conditioned bottle leaves this sediment undisturbed). The cask is no different.

In the graphic below, there is sediment on the bottom, yeast in the beer and CO2 coming up from the bottom. When the cask is first bled of excess CO2 by tapping a wooden dowel into the top of the cask. As you can imagine, the CO2 bubbles up stirring up some of the sediment on the bottom.

If you click on the image below, a new window will open and the video will show you internally what happens when a cask is vented.

As you can see, the initial bleeding of CO2 causes it to come out of the beer and it brings sediment up with it. This is why a cask is left to settle after venting for a good bit of time (hours-days depending).

The cellarman’s job is to bled off excess CO2, allow the sediment on the bottom to settle and to get the yeast to drop. In the end, the beer should be clear, actually more than clear. The English term for this is ‘dropped bright’.

Casks are set in place and are not moved until they are empty. As you can imagine, bumping or moving the case will cause clarity to suffer.