What a great time I had brewing here. Good people to work with. Great equipment and great processes implemented. I learned a lot.

Here are the fermentors. I’m on the mezzanine looking to the front of the brewery. It’s a panoramic shot so click on it to see the full image.

Once the mash is done, the wort get pumped to the copper or boil kettle.

The heat exchanger and lot of other control valves and switches alone with the temperature indicators of the HTL and chilling water

After the boil, the wort is chilled and oxygenated while being pumped to the fermentor.

Here is a short video showing the wort with air passing through a site glass.

When you start moving the cooled wort through the tubing system, the tubing system is filled with sterilized water, so the wort is pushing the water through the system. This contraption is used to allow you to flow the water onto the floor and when wort starts coming out you flip the valves and divert it into the fermentation vessel.

And next we get the yeast that will be dumped into the top of the fermentation vessel (FV).

I’m gonna back up and cover some earlier parts of the process.

I was very impressed with the way the design of this brewery handles the malted grain.

The pallets of grain are taken off the delivery truck and fork lifted onto the mezzanine. This is where all of the grains are kept and where the manhole is to drop the grain into the mill.

We weighed out grain with a scale and dropped it into this hole to get milled.

This is where the grain goes to after you put it down the hole.

This is where the grain goes to after you put it down the hole.

It is in the hop storage cold room. You can see grain dropping into the mill here. The two knobs are to adjust the gaps. On the left, the green shaft is an elevator that lifts the grain up into the grain bin that is above the mash tun.

Up on the mezzanine, this is the same shaft. On the left, the grain bin holds the grain until it’s needed to drop into the mash tun and be mixed with water of a certain temperature.

In the video below which is very foggy due to the steam from the hot water, you can see the last piece of the grain dispensing which has a hose with water that is 77c degrees attached to it. The grain and the water blend and create a mash that is (in this case) 69.3c degrees.

Here is a really big bag of East Kent Goldings that I pulled hops from to be weighed.In fact, I pulled 7 kilos for this brew along with 2.5 K of Brambling Cross and half a kilo of Fuggles. These additions were at 75 minutes (start of boil), 5 minutes and 0 minutes.

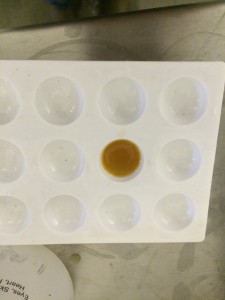

I took an iodine test since everything was there that I needed.

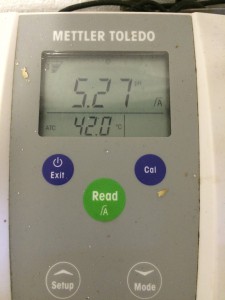

We took pH readings at various points in the process.

Of course there was a lot of cleaning. All the grain had to be dug out from the mash tun and the hops from the boil kettle. Here is a shot of me in the boil kettle cleaning.

I also had a chance to visit the hop farm that they get their hops from. Keep in mind it is the off season. Just look at all the stringers support structure.

Gadds was a great experience for me.

You must be logged in to post a comment.